Pipeline expansions are essential for meeting rising energy demands, but they bring a unique set of challenges when it comes to leak detection. In one of our recent projects, a major North American operator undertook a large-scale pipeline expansion, adding nearly 600,000 barrels per day of capacity while simultaneously maintaining the integrity of its existing pipeline system (see Figure 1).

Figure 1: An overview of the expanded pipeline network, illustrating the addition of nearly 600,000 barrels per day capacity alongside existing infrastructure

With increased throughput and the added complexity of a parallel pipeline system, ensuring robust and reliable leak detection was a priority from day one. In this blog, Team Manager Lisa Becker uses a real pipeline expansion project in North America to discuss the value of early leak detection.

Building a leak detection system for pipeline expansion

For this operator, regulatory requirements played a significant role in shaping the approach to leak detection. In compliance with strict national regulations, the operator needed to implement a computational pipeline monitoring (CPM) leak detection system that met API 1130 standards for sensitivity, accuracy, and reliability.

Atmos Pipe, an advanced statistical leak detection system enhanced by machine learning, was deployed across both the new and existing pipelines. Together, these solutions provided a holistic view of pipeline performance and potential leak scenarios.

Integrating new and existing pipelines

The expansion project included 988 km of new pipeline and the reactivation of 193 km of existing line along with new pump stations and tank terminals. This created a complex network of operational pipelines that required consistent leak detection standards. As the pipelines transport multi-products, accurate batch tracking is also essential for the operators.

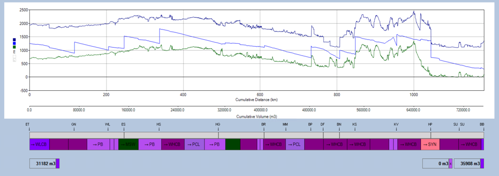

Atmos Batch tracks the head and tail of each batch and provides the estimated time of arrival (ETA) at each delivery station. Figure 2 shows the hydraulic profile of the pipeline together with the batches.

Figure 2: A screenshot of real time batches in the line as well as the hydraulic profile along the line

Atmos worked closely with the operator to:

- Develop comprehensive tag management, ensuring consistency across all stations and sites.

- Implement redundant OPC servers and SCADA systems to ensure reliability.

- Conduct rigorous factory acceptance testing (FAT) and linefill simulations to validate system readiness before start-up.

From construction to operations: fine-tuning for real-world conditions

No project is without its challenges. During construction, issues like horizontal directional drilling (HDD), pipe diameter changes and evolving operational conditions required adaptable solutions. Frequent project meetings, change management protocols and hands-on engineering support from Atmos ensured that leak detection systems were integrated smoothly and efficiently.

Post-startup, the system underwent additional tuning to account for real-world conditions, with daily adjustments to refine leak detection thresholds and alarm settings. Maintenance contracts were established to provide continuous technical support, ensuring the operator could respond quickly to any issues.

Lessons learned: the value of early engagement

A key lesson from this pipeline expansion project is the value of starting leak detection planning early. By integrating leak detection considerations into the design and construction phases, the operator avoided costly retrofits and operational delays. Early involvement allowed Atmos to:

- Develop consistent tag standards and master tag lists.

- Simulate real-world scenarios using test environments before commissioning.

- Provide on-call engineering support during the critical start-up phase.

Prioritize leak detection in every pipeline expansion project

Major pipeline expansions bring opportunities to increase capacity and open new markets but they also introduce complexities that can impact leak detection performance. By partnering with Atmos from the outset, this operator ensured that its expanded network met regulatory requirements and maintained high standards of operational integrity.

Whether it’s a new pipeline or an existing one, Atmos’ solutions help operators manage complexity, maintain compliance and protect the environment.

Learn more about Atmos’ leak detection solutions for complex pipeline projects