Written from the field by Senior Project Engineer Oliver Port

How 0.03 seconds of pressure data revealed pipeline stress

Not every leak comes without warning. Sometimes the first sign is a sharp, brief pressure spike, gone in milliseconds but critical to what happens next.

During our water hardware trial on a rising sewer main in the UK, a transient event lasting just 0.03 seconds revealed previously unseen pipeline stress, which we later confirmed to be the cause of a leak.

This blog explores how high resolution pressure monitoring helped us predict a failure before it fully developed and why fast, fleeting signals shouldn’t be ignored.

The split-second surge that became a warning signal

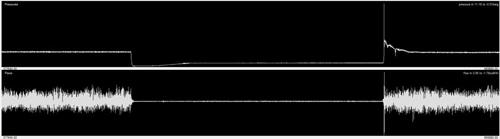

Our water hardware was monitoring pipeline conditions as the pumps restarted when it detected a pressure surge that jumped from the normal 2 barg up to over 11 barg (see Figure 1). The spike lasted just two scans, equivalent to 0.03 seconds, but was enough to trigger an overpressure alarm.

Figure 1: Overpressure transient detected by the water hardware, spiking to 11 barg for just 0.03 seconds at pump startup. This event triggered an alarm and preceded a real leak. The third chart is a zoomed in, one second sample of the pressure spike seen in the top chart.

The consequence: a leak outside the pumping station

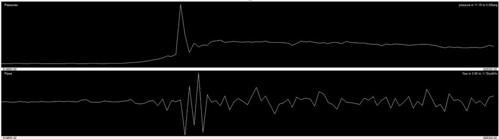

A few days after that alarm, our water hardware detected a leak at the same site. Field teams later confirmed sewage had overflowed from a valve chamber outside the pumping station (see Figure 2).

Figure 2: Valve pit outside the pumping station overflowed days after the pressure spike was recorded, later confirmed as a leak detected by the water hardware.

The pressure spike likely stressed the pipe wall or dislodged a weakened seal, setting the stage for pipeline failure. Without high resolution monitoring, we wouldn’t have known the pressure surge had occurred.

Why high frequency data matters

Unlike traditional loggers that sample slowly, Atmos' water hardware collects high frequency data up to 480 Hz and processes it on the device itself (Edge processing). That means short-duration events like this aren’t lost in the noise or smoothed over by low-resolution trends.

Catching the causes of leaks is a core component in the prevention of future leaks. By avoiding pressure surges when starting up pumps the number of leak events could be reduced.

Engineering insight in milliseconds

This event shows how vital fast data is to understanding asset health. It provides a clearer view of what happens during pump start-ups and transient conditions, moments that standard Supervisory Control and Data Acquisition (SCADA) monitoring typically ignores. It also validated Atmos' water hardware's overpressure module, which didn’t just raise a flag but helped tie a cause to the consequence.

Next up: The leaks you can’t see

Not every leak starts with a bang. Some barely register but can still cause long-term damage. In the next blog, I’ll walk through how Atmos Sentinel picked up a leak representing just 1% of reference flow and why sensitivity matters as much as speed.