Complying with API standards

Pipeline leak detection and incident response is a crucial consideration for operators. Not just to be able to keep the people, public and environment safe from the effects of ruptures and leaks, but also, from a business point of view to be able to comply with regulations.

The American Petroleum Institute (API) represents all segments of America’s oil and natural gas industry1. The standards are recognized for being technically stringent and its third-party accreditation, which is accepted by states, federal and increasingly international regulators2.

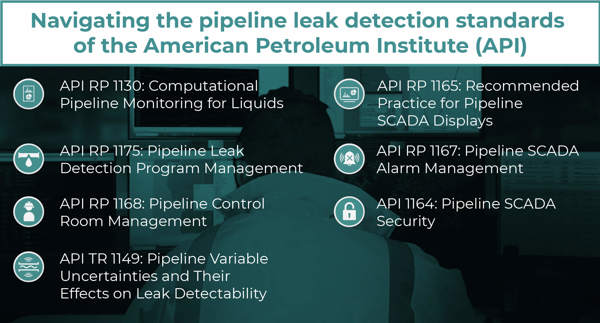

There are seven standards that affect pipeline leak detection compliance and following best practice with API. Failure to comply with the ones that are required leads to a 60 day period to ensure compliance. After this period, if the pipeline operator still doesn’t comply it can result in serious financial penalties and reputational damage to the organization.

In this article we’ll discuss each API Recommended Practice (RP) and Technical Report (TR) standard to help pipeline operators navigate them.

- API RP 1130: Computational Pipeline Monitoring for Liquids

- API RP 1175: Pipeline Leak Detection Program Management

- API RP 1168: Pipeline Control Room Management

- API TR 1149: Pipeline Variable Uncertainties and Their Effects on Leak Detectability

- API RP 1165: Recommended Practice for Pipeline SCADA Displays

- API RP 1167: Pipeline SCADA Alarm Management

- API 1164: Pipeline SCADA Security

API RP 1130: Computational Pipeline Monitoring for Liquids

Originally API RP 1155, API RP 1130 replaced the old regulations in 2007. API RP 1130 defines that a uniform methodology can be used by pipeline companies to effectively evaluate pipeline leak detection systems (LDS), referred to as computational pipeline monitoring (CPM) by API. On April 28, 2022 API published its revised edition.

The standard splits leak detection systems into two categories:

- Internally based eg flow, pressure or fluid temperature sensors

- Externally based eg infrared radiometers or thermal cameras, vapor sensors, acoustic microphones or fiber-optic cables

Only the internally based systems are included in the standard. The focus is on the design, implementation, testing and operation of LDS that use an algorithmic approach to detect the hydraulic anomalies in pipeline operating parameters. It is intended that the LDS would provide an alarm and display relevant data to help aid decision making, so that pipeline operators can quickly respond to the hydraulic anomaly.

The recommendations include a criteria that spans a detailed performance criteria for the LDS, which includes:

- Sensitivity - Small leaks should be detected within a short period

- Precision - Leaks are located precisely and the system can indicate leakage rate, plus the product that is escaping

- Robustness - The LDS should continue to actively monitor in non-ideal conditions and unsteady operating conditions like temperature fluctuations, changes in viscosity and sensor failure

- Reliability - False alarms should not be generated despite the high sensitivity

Federal regulators, including the Pipeline and Hazardous Materials Safety Administration (PHMSA), have recently put renewed focus on leak detection for natural gas and liquid pipelines. RP 1130 supports PHMSA’s priorities by putting additional tools and leading practices in the hands of operators to monitor and manage potential liquid pipeline leaks more effectively.

API RP 1175: Pipeline Leak Detection Program Management

This RP provides guidance for pipeline operators to create effective leak detection programs (LDP), with the aim of identifying leaks quickly and with certainty, facilitating a rapid shutdown and minimizing negative consequences in the event of an incident. The goal is for the pipeline operator to run their pipelines safely and reliably so there are no adverse effects on the public, employees, environment or pipeline assets.

To comply with this standard, it is important that pipeline operators understand:

- Pipeline vulnerabilities and risks

- Program management best practices

API released the second edition standard on April 28, 2022 together with RP 1130 in response to the request of the US Department of Transportation and Pipeline and Hazardous Materials Safety Administration (PHMSA) to address LDS response effectiveness. The documentation that encompasses this standard provides a high-level overview of liquid pipeline LDPs and encourages pipeline operators to go beyond, so that leaks are detected quickly, with certainty and so that the pipeline is shutdown as quickly as possible to minimize negative impacts.

Often API documentation is frequently cited or even adopted by other numerous regulating authorities globally to set leak detection standards, so it’s likely that this standard may become useful in countries other than the US and Canada.

Main sections of API RP 1175 include:

- Definitions

- Leak detection culture and strategy

- Selection of leak detection methods

- Performance targets, metrics, and KPIs

- Testing

- Alarm management

- Roles, responsibilities and training

- Reliability centered maintenance (RCM) for leak detection equipment

- Overall performance evaluation of the LDP

- Management of change

- Improvement process

API RP 1168: Pipeline Control Room Management

This standard provides pipeline operators and control room staff with guidance on industry best practices for control room management. This should be considered when developing or enhancing processes, procedures and training.

It addresses pipeline safety elements in pipeline control rooms for hazardous liquid and natural gas pipelines in both the transportation and distribution sectors:

- Pipeline control room personnel roles, authorities and responsibilities

- Guidelines for shift turnover

- Pipeline control room fatigue management

- Pipeline control room management of change

API TR 1149: Pipeline Variable Uncertainties and Their Effects on Leak Detectability

API TR 1149 deals with the uncertainties of various elements of the pipeline and how they affect leak detectability. The standard uses the simple mass balance technique to calculate a theoretical leak detection limit, considering instrument inaccuracies and the physical characteristics of a pipeline.

Leak detection sensitivity >= Steady state uncertainty + Transient uncertainty

This TR is designed for crude oil and refined products. It is limited as it doesn’t account for temperature and is only for steady state operation. In addition, the standard focuses on single, straight pipelines and the material balance method of CPM (while discussing other ancillary issues), particularly under steady state conditions.

The initial API publication of TR 1149 had several gaps in justifying the sensitivity estimation metrics. Its most recent release addresses these to improve the ability to qualify sensitivity estimations of many CPM applications:

- The need to cover the complete range of CPM methods in current, practical use

- Extended assessment of highly volatile liquids and natural gasses

- Alignment of definitions and approaches to uncertainty with those used systematically in instrument and measurement engineering

- Recognition of the non-linear and strongly time dependent nature of certain engineering factors

- Inclusion of several engineering factors that occur regularly in pipeline operations

- The inclusion of the major supervisory control and data acquisition (SCADA) uncertainties in measurement

Section 7 of the standard document provides guidance on the source of uncertainties in different types of sensors and measurement systems. It also discusses the presumed normal distributed errors, pertaining to forecasting false alarm estimates. In addition, it addresses the issues related to how this does not readily relate to false alarm rate, particularly with consideration of these statistical outliers.

API RP 1165: Recommended Practice for Pipeline SCADA Displays

This RP focuses on the design and implementation of displays, monitoring, and control of information on pipeline SCADA. It outlines industry practices that guide a pipeline operator who wants to select a new SCADA system or update their existing one. The main impact of this standard on leak detection is the access and display of leak alarm, leak size and location estimates.

API RP 1167: Pipeline SCADA Alarm Management

Pipeline operators are recommended to follow industry best practice in the development, implementation and maintenance of alarm management. This standard provides guidance on elements that include:

- Alarm definition

- Philosophy

- Documentation

- MOC

- Auditing

The main impact of this standard on leak detection is the generation, acknowledgement, acceptance and archive of leak alarms.

API 1164: Pipeline SCADA Security

The main body of this standard provides a high-level view of holistic security practices. Following the guidance outlined in the annexes assists in creating inherently secure operations. Implementing this standard to advance SCADA cybersecurity is not simple, or a one-time event, but a continuous process.

Ideally, it would be started as part of a SCADA upgrade project and used to ‘design in’ security as an element of the new system. Cybersecurity is essential for the availability and reliability of leak detection systems.

Continuous pipeline leak detection for API standard compliance

Ensuring compliance with these standards is a continuous process, and while some larger pipeline operators may have a dedicated leak detection team, they still have day-to-day tasks integral to the pipeline operation. This could result in knowledge gaps forming and a culture of compliance not being embedded into the organization. In addition, compliance is not just limited to API RP 1130, API RP 1175 and CSA Z662-19 Annex E, sometimes more specialist knowledge is required to comply with the other standards outlined.

A regulation compliance service can provide a bespoke approach that covers:

- Compliance statements

- Necessary procedures

- Testing programs

- Training

- Gap analysis

- Rescue programs to support pending audits

If you’d like to find out more about Atmos International’s compliance service for all leak detection systems, regardless of vendor, contact us now.

References