What is a parametric study?

A parametric study is a series of automated simulations with varying parameters where the parameter range and any constraints can be defined. Parametric studies allow you to analyse the calculated results of the simulation that are of specific interest and present these results in a concise format for evaluation.

A parametric study requires the following:

- Design objective

- Parameters nominated for use in the simulation

- Parameter ranges identified

- Design criteria specified

- Various configurations generated

With most simulation applications this type of study requires multiple configurations, with each configuration containing a variation in the input parameters. The simulations are executed concurrently and the results post-processed manually. Even for a simple study, such as the evaluation of a case with ten variations in one primary parameter, for example ten different modes of compressor operation in a gas network, this can be a time consuming and laborious task particularly if you need to further refine the parameters or design constraints until satisfied with the results.

Atmos SIM provides a solution to the issues faced when performing parametric studies by providing the ability to configure multiple scenarios in a single configuration, running the simulations in parallel, and presenting results in a user-friendly, easy to read format.

In this article we are going to look at the following two examples of how to conduct a parametric study in Atmos SIM:

- Case example 1 - emergency shut-down (ESD) surge analysis with varying valve timings

- Case example 2 - network capacity analysis with varying hydrogen/natural gas blends

Case example 1

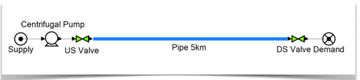

A simple A-B pipeline with an upstream pump and two isolation valves can be seen in figure 1 below:

Figure 1: case example one’s pipeline

Variables to be modified

- US Valve travel time

- DS Valve travel time

Variable range 1 second to 60 seconds and variable resolution to one second.

Variable to be analysed

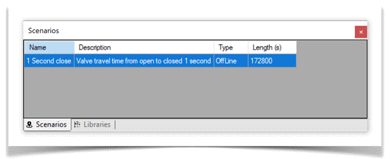

Maximum surge pressure in pipe. A scenario is created for the first case via the Atmos SIM GUI as shown in figure 2 below:

Figure 2: scenario creation

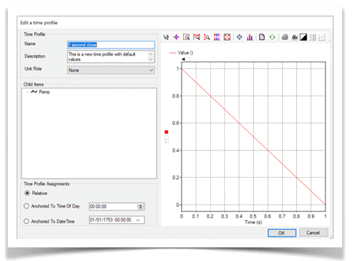

A time profile is then created to vary the valve position over a one second duration.

Figure 3: time profile creation

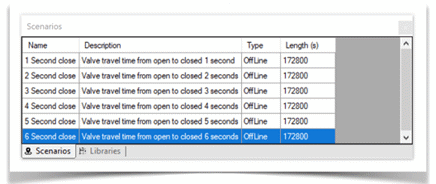

This is repeated for all 60 cases using the scenario tool:

Figure 4: multiple scenarios created in a single configuration

The next stage is to run the simulations. In most applications this would be a case of opening each of the 60 simulation files in turn and running the simulations, however Atmos SIM provides a dedicated tool to run multiple scenarios in parallel.

Atmos Surge Analysis is an additional module available as a bolt-on to Atmos SIM Offline. Atmos SIM Offline has a wide range of functionalities and can be used for pipeline design, equipment sizing and locating, operational design, operational tuning and training.

Atmos SIM’s Surge Analysis module has been purpose built to simplify and automate the process of submitting a detailed report to the relevant authorities, as required by law. The single-minded focus behind its development has led to the ultimate tool for surge analysis. It works by scheduling the running of a series of scenarios such as valve closures and pump trips. The schedule is then run and the data for each scenario is analysed for pass and failure criteria. A report is then generated automatically, where the data is displayed graphically in trends, pipeline maximum pressure points are located and pump trip times are identified.

System outputs from the Atmos Surge Analysis module

A full report is automatically generated in Microsoft® Word, PDF or other formats. This includes charts and tables that can be easily added to other studies and reports, such as health and safety documentation.

Figure 5: Atmos Surge Analysis tool and report output

Case example 2

A parametric study using Atmos SIM is not constrained to surge analysis. In this second case we will look at the implications of varying hydrogen blends on the capacity of a gas network.

There is little doubt that transportation of hydrogen blends is going to have a significant impact on the pipeline industry. For years, operators have looked at meeting future energy demand using natural gas from traditional sources, domestic production, imported gas and LNG, however the landscape has now changed.

A blend of 25% hydrogen will reduce the heating value of natural gas by approximately 15%, or put another way, volumetric demand will need to increase by more than 15% to meet current energy demand. Will the existing pipeline infrastructure cope? We will use an Atmos SIM parametric study to find out.

Figure 6: theoretical transmission network

Here we have a theoretical transmission network, currently transporting natural gas, that will potentially be repurposed to transport hydrogen/natural gas blends. What we need to know is: can the network cope with predicted future demand and how will the concentration of hydrogen affect network capacity?

There are three core considerations for understanding how the network will cope with future demand and how hydrogen will impact network capacity. They are:

- Supply locations

- Network topology

- Demand pressure requirements

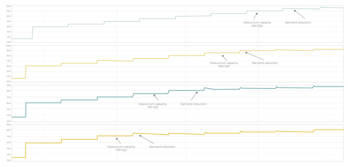

The parametric study to be performed is a transient gas network simulation for varying hydrogen blends. In this case four different concentrations of hydrogen were considered, but a more detailed study covering 0-100% hydrogen could be conducted easily.

The starting case uses the current maximum daily quantity (MDQ) at all demands.

Total demand is increased every 24 hours, divided up as per the starting state. Atmos SIM makes this task easier with demand groups. Once the minimum pressure constraint is violated, the demand is reduced to maintain pressure. The point this happens is deemed as maximum capacity.

Figure 7 demonstrates the maximum capacity is reduced as hydrogen concentration increases, calculating the capacities as:

- 100% natural gas 900 Tj/day

- 10% hydrogen 850 Tj/day

- 25% hydrogen 750 Tj/day

- 50% hydrogen 700 Tj/day

Figure 7: hydrogen blend maximum capacity calculated by Atmos SIM (red 0%, green 10%, blue 25% and orange 50%)

A clearer future for pipeline operations

Embedding parametric studies into pipeline operations enables pipeline operators to plan for a range of scenarios through the use of simulations where any constraints can be defined. Once it receives the necessary input parameters, a parametric study uses simulation software to conduct automated simulations, saving pipeline staff time and effort in the process.

Atmos SIM in particular has the facility to configure multiple scenarios in one simulation and, as seen in Figures 1 and 2, can perform parametric studies to assist in surge analysis and the assessment of network capacity.