The changing composition of oil, water and gas in multiphase products has historically made leak detection very challenging on multiphase pipelines.

The project this year where Atmos successfully installed a Pipeline Guardian leak detection system with proprietary non-intrusive pressure sensors on a multi-phase pipeline is one example of a proven solution to this challenge. When tested with product withdrawals, the pressure-based system successfully detected the test leaks.

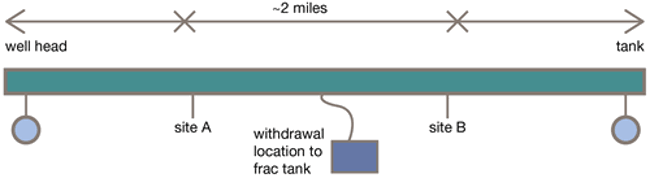

The 2-mile-long pipeline is classed as a high consequence area as it carries a mix of oil, gas and water directly from the wellhead to a tank in a pipeline that crosses a river.

Figure 1 Layout of the pipeline

Figure 1 Layout of the pipeline

The leaks were simulated by diverting product into a tank located near the center of the pipeline.

The sensor uses an advanced strain gauge capable of measuring minute changes in the loading of a pipe wall. Combined with high-resolution data logging and proprietary digital signal processing algorithms, the non-intrusive sensor detects very small pressure changes. Working with Atmos Wave leak detection software, the sensor tracks progressive pressure changes that occur over long periods of time. These are signatures associated with slow leaks and continuous small diameter thefts beyond the detection capabilities of most leak detection systems.

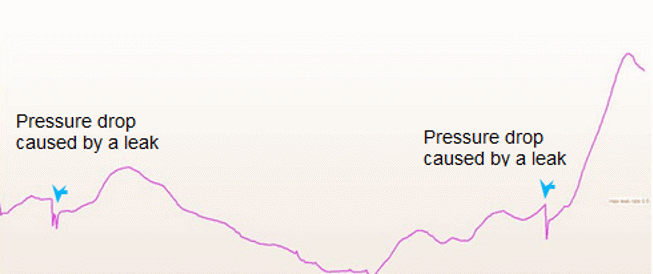

Figure 2 Examples of the leaks detected by non-intrusive pressure sensors in a Pipeline Guardian leak detection system

Figure 2 Examples of the leaks detected by non-intrusive pressure sensors in a Pipeline Guardian leak detection system

The sensor can be installed with a Pipeline Guardian unit for data logging, data transfer, and remote power supply options to support leak detection anywhere, even on pipelines with no power, instrumentation, or communications.

No drilling, welding, or cutting required

These unique sensors can be installed within hours and begin transmitting pressure measurements immediately with zero operational down-time. The installation site requires only 1m of straight pipeline. Flexible outer linings or servi-wrap on the pipeline can remain intact. No industrial cleaning or abrasion is required prior to attaching a sensor.

The sensors can provide the field pressure data to support an effective leak detection system much faster than a traditional project and without expensive installation costs, making them ideal for leak detection on the short pipelines in multi-phase gathering systems where the high cost of multi-phase flow metering has made leak detection impractical in the past.