Written from the field by Senior Project Engineer Oliver Port

Detecting short-lived leaks

Some leaks can be easily detected, while others are harder to spot, opening briefly, then closing again before they cause a visible issue. This is especially common in wastewater pipelines, where many short duration leaks are plugged by a buildup of things like wet wipes, fats, oils and grease.

These short-lived, intermittent failures can be especially challenging to detect, particularly on pipelines with limited access like rising sewer mains.

During a field trial, our water hardware managed to capture a large pressure drop which was followed by a rapid recovery, revealing the presence of a leak that may otherwise have gone unnoticed and demonstrating why real-time monitoring matters.

A short drop in pressure can indicate a clear warning

The hardware recently recorded a 2.5 barg pressure drop, followed by a return to normal conditions within just five seconds. Alongside the pressure change, an increase in pumping rate was observed, another key indicator that water had been lost from the system (see Figure 1).

Figure 1: The detection of a 2.5 barg pressure drop was followed by a rapid pressure recovery and increased flow within 5 seconds, which is consistent with a brief, self-sealing leak

Although the pressure quickly stabilized, the hardware's rapid leak detection algorithm flagged the event and triggered an alarm. The short duration of the leak suggests it may have been caused by a quick reseal that allowed the pressure to recover to operational levels.

This is a good example of a self-sealing leak, an event that’s difficult to confirm, but important to log and investigate.

Short-term leak events still matter

On a system without high-resolution monitoring, a five second leak like this would almost certainly go undetected. A logger sampling once a minute wouldn’t catch the pressure drop or the recovery.

In comparison, our water hardware sampling pressure at a high frequency processes the data locally. That means it can spot fast-moving events like this in real time and raise the right alarm at the right moment.

For water utilities, real-time monitoring provides another layer of insight, not just into whether a pipeline has failed catastrophically, but how less severe failures can occur frequently and go under the radar.

Understanding the data

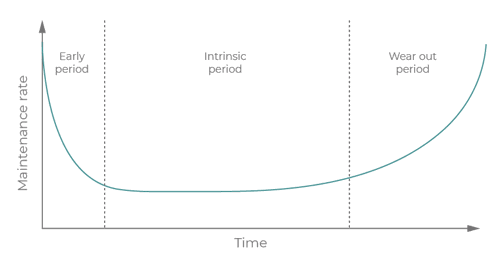

Just because a leak stops doesn’t mean it didn’t happen. Intermittent failures are often a sign of a pipeline under stress, whether it’s from pump activity, transient conditions or aging infrastructure (see Figure 2).

Figure 2: A visualization of the bathtub curve, as used to define the reliability of a product as it ages

Spotting these failures early gives operators the chance to:

- Investigate weak points before they become permanent failures

- Understand how the system responds to pressure events

- Prevent recurring issues from escalating into severe pollution incidents

Next up: field-confirmed detection

In the next blog of my insights in wastewater from the field, I’ll take a look at a leak that was first detected by our water hardware, then confirmed during a site visit. It’s a reminder that combining live monitoring with field validation remains the most effective way to manage difficult pipeline assets.