The challenges facing leak detection in multiphase pipelines

With the increasing need to respond to climate change and reduce greenhouse emissions, effective leak detection in pipelines, especially multiphase pipelines, has never been more critical.1

Multiphase pipelines remain a popular form of fluid transportation because they can operate in a wider range of scenarios than single phase lines and transport a mixture of gas, oil and water.2

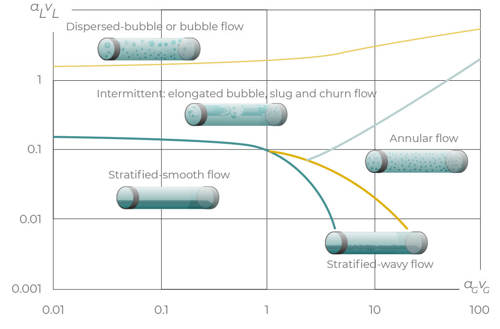

Figure 1: An example of a multiphase pipeline’s steady-state flow regime ma

The wide range of scenarios available to a multiphase pipeline is also one of the main reasons why little progress has been made for leak detection in multiphase pipelines in recent decades.

As seen in figure 1, a leak detection system that meets certain performance specifications is difficult for pipeliners to select and maintain because multiphase lines run under different flow regimes at different times.

Another challenge facing leak detection systems in multiphase pipelines is the high cost and poor performance of instrumentation. For example, to achieve a similar flow meter accuracy to single phase lines it is necessary to separate gas, water and oil at the inlet and outlet of a multiphase pipeline.

Unfortunately the best multiphase flow meters (MPFM) available can only deliver an accuracy between two and five percent, the price for one MPFM is upwards of 100,000 US dollars, the more accurate flow meters contain gamma which requires careful supervision and maintenance.

Over the past few years significant research and field tests have been completed to develop solutions which address the challenges to leak detection systems in multiphase pipelines.

Here we will discuss the technologies tested on three multiphase pipelines:

- Multiphase pipelines with separators

- Offshore multiphase pipeline

- Onshore multiphase pipeline

Multiphase pipelines with separators

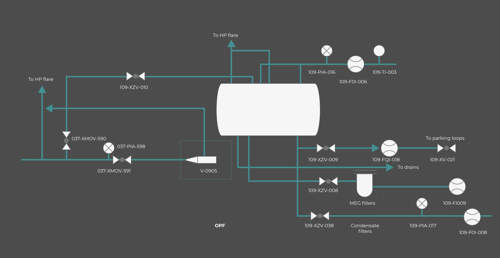

In the example of two 30 inch, 21 km long multiphase pipelines, the operator had decided to measure gas, condensate and MEG separately at the inlet before combining them for input to the export pipeline.

The export pipeline receives the multiphase flow via a pig receiver, which is then separated into the three phases using a separator so that gas, condensate and MEG are measured separately.

Figure 2: Schematic diagram of the metering process for the gas, condensate and MEG

Flow and pressure measurements are available at both ends of these two pipelines so Atmos Pipe statistical pipeline leak detection system is used.

Liquid slugs are a challenge in the maintenance of a reliable leak detection system on these two multiphase pipelines. They are formed and arrive at the receiving terminal due to pigging, terrain induced slugging and restart and ramp up surges.

The advantage of Atmos Pipe leak detection systems is that they can be tuned to cope with the slugs without false alarms. For both pipelines, no leak alarm is generated by the pigging operation and the accumulation of liquid slugs.

Offshore multiphase pipeline

In 2019 Atmos carried out a trial on an offshore multiphase pipeline in the US. The pipeline was 8 inches in diameter and 2.5 km long. It transports mostly oil and water with a small fraction of gas.

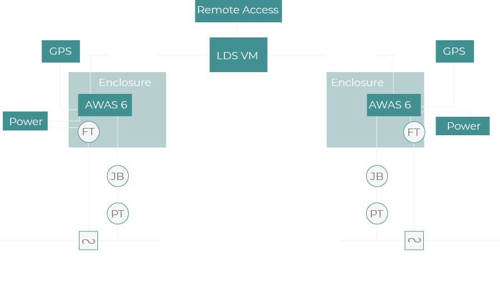

There was no instrumentation on this pipeline when Atmos began this trial, so a dynamic pressure sensor and Doppler flow meter were installed at the inlet and outlet together with GPS antenna for reliable leak detection and accurate leak location.

Figure 3: The instrumentation system setup for the multiphase pipeline leak detection trial

The flow and pressure data were sent to a workstation where the negative pressure wave leak detection system was installed. Between March and October 2019, the quality of the operational data was analyzed, assessed and it was found that while the flow meter readings were useful for wave direction indication, they provided little insight into flow-based leak detection.

Flow data from the clamp-on Doppler meters displayed a presence of gas bubbles at the outlet which presented the possibility of a 35% discrepancy between the inlet and outlet flow readings. This led to negative pressure wave leak detection being added to the pipeline using the flow and pressure data. The flow meter readings are used in parallel with the pressure to distinguish leaks from routine operational changes.

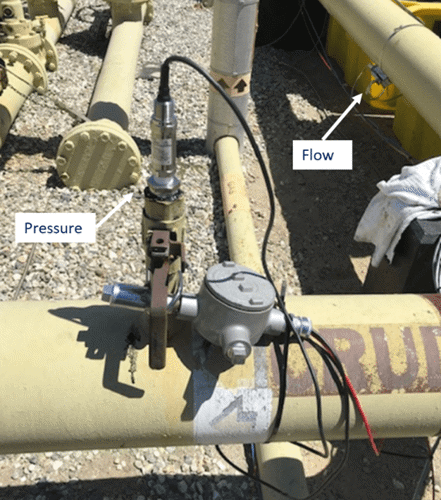

Figure 4: Installation of the pressure and flow meter

Multiple fluid withdrawal tests were conducted with the support of the operator to identify the threshold for the smallest leak detectable while raising none or the fewest false alarms. Conclusions from the data analysis and leak tests were that a leak of 3% could be detected on this multiphase pipeline with a substantially low level of false alarms. The price of the instrumentation was also similar to what would be used on single-phase pipelines.

Onshore multiphase pipeline

This customer operates an onshore, multiphase NP 6 pipeline that runs under a river so there’s a greater requirement for an effective leak detection system. The pipeline is only 3.7 kilometers long but has an elevation change of 70 meters during its transition underwater which results in changes in the fluid flow regime along the pipeline. This presents a challenge in the development of a leak detection system without component metering and mass flow balance.

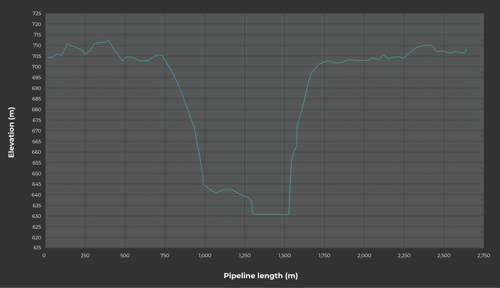

Figure 5: Multiphase pipeline elevation profile - a 70 meter drop at the river crossing

Not only that, but the pipeline contains a highly variable mix of oil and gas where the flow regime is not fixed and varies between elongated bubble, slug and churn flow. This is one of the most challenging scenarios for effective leak detection so it led to a four-year research project between the customer and Atmos.

One pressure sensor was installed on each side of the river when the initial investigation started in 2018. Leak trials tested the negative pressure wave system’s capabilities and out of eight generated leaks, only one leak was detectable by the system. Elongated gas bubbles caused by the variable composition of oil and gas were found to be impacting the pressure-based system performance so recommendations were made to add two pressure sensors on the pipeline.

New additional pressure data allows the leak detection algorithm to check negative pressure waves against all available pressure sensors and deduce if the event is operational or a leak, improving reliability when working with a multiphase flow scenario.

More leak trials were conducted with the additional two pressure sensors and the results showed that the negative pressure wave system detected most of the controlled leak while maintaining a low false alarm rate.

To reduce the minimum detectable leak size without increasing false alarm rate, further research was carried out at the customer’s request which considered the following areas of improvement:

- Field instrumentation

- Pipeline operations

- Inline inspection tool

Together with our customer’s transition to smoother operations, it was found that the negative pressure wave system could sufficiently detect smaller leaks without increasing the false alarm rate.

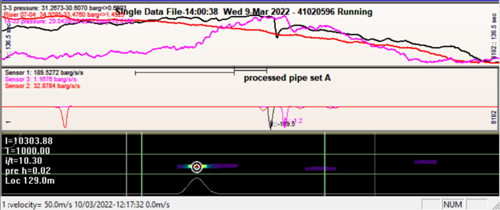

Figure 6: The detection of a smaller leak

Multiphase pipelines also typically carry out pigging to clean the pipelines of debris and stagnate liquids. Atmos developed an acousting sensing pig, an offline leak detection tool that could detect even smaller leaks that would go unnoticed by the online system. Much like the solutions reached on the offshore pipeline case discussed earlier, this is cost effective and easily deployed on site because it’s smaller and could be attached to a cleaning pig before routine pigging.

The above research and field tests were carried between 2018 and 2022, concluding that the negative pressure wave system together with offline inspection tools like the accoustic sensing pig can accurately detect leaks while raising minimum false alarms. The online system went live in March 2022 and no false alarm has been generated.

Changing the future of leak detection on multiphase pipelines

Although leak detection in multiphase pipelines presents a risk of high cost, complexity and inaccuracy, Atmos has carried out three projects that demonstrate the achievability of a reliable and sensitive leak detection system.

To learn more about new findings in leak detection on multiphase pipelines download the paper in full as first presented at the International Pipeline Conference and Exposition 2022.