Written from the field by Project Engineer Olivia Heaney

Can portable hardware pick up the smallest leaks in real conditions?

I recently took Atmos Odin units out to a UK site where the operator wanted to see if leak detection could work for them. They didn’t have much instrumentation on the pipeline prior to this and were conducting physical line walks to detect leaks. External methods such as this should be viewed as complementary rather than a standalone approach to leak detection.

The aim was to install Atmos Odin units for the customer, run a survey and collect valuable pressure data. The question was simple: what sensitivity could we achieve for a leak detection system on this pipeline?

Setting up the leak sensitivity pilot

The site had limited instrumentation, which made it an ideal place to use Atmos Odin because the customer didn’t have any way to monitor pipeline operations previously, so this was a unique opportunity to get insight into the hydraulic behavior within the pipeline.

Within a day we installed units on two lines (see Figure 1), ran a full site survey and gathered the information needed to understand both performance and any civil requirements for a permanent system, which would also include non-intrusive flow measurement to provide two methods of leak detection.

Figure 1: Atmos Odin units installed on both pipelines

Collecting leak detection data

Atmos Odin units are standalone, so we didn’t need to interfere with existing equipment. Once installed, they immediately began storing data. Over the course of a week, we collected data which allowed us to see a range of operations with different flow rates and average pressure (see Figure 2).

Figure 2: Data collected by the Odin units over 13 hours. The middle chart shows a zoomed-in view of the data highlighted by the grey box in the top trend. The bottom chart shows the same data range as in the middle chart, but with a noise filter applied.

What we found

On one pipeline Atmos Odin detected changes as small as 0.08 bar, approximately a 1% leak rate (visible in the center right of the bottom chart in Figure 2). On the other pipeline it was even more sensitive, displaying the capability of detecting a leak rate of approximately 0.5% in steady state conditions (see Figure 3).

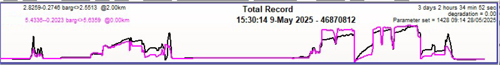

Figure 3: Pressure data from the full data collection period on the other pipeline over three days and two hours

These results gave the operator confidence that leak detection could work even on a pipeline that previously seemed too noisy or complex to monitor.

Why it matters

For me, the value of this pilot was in showing how quickly and simply we could move from installation to meaningful results. Atmos Odin proved effective in showing the capabilities of negative pressure wave leak detection, offering leak sensitivity without the need for costly civil works or major new infrastructure.

Where sites already have some instrumentation in place, our Atmos Black Box units can connect to it directly, streaming data into the same analysis framework.

Lessons from the field

This trial confirmed that leak detection doesn’t have to be complicated or expensive to be effective. Sometimes all it takes is a small pilot with the right hardware.

The success of this trial is a practical reminder that building confidence in leak detection often starts with a simple pilot, carried out where it matters most: on the pipeline itself.

Learn more about the leak and theft detection capabilities of Atmos Odin