Combatting climate change while maintaining pipeline operations

Keeping the lights on, homes warm, plants running, planes flying and water running wouldn’t be possible without operational pipelines. They’re one of the safest means of transporting a gas or liquid.

To help combat climate change while maintaining pipeline operations, cost-effective and efficient actions can be put in place by pipeliners to reduce greenhouse gas emissions.1

Here we will look at solutions which implement existing software tools or require minimal investment in a new software, including:

- Leak detection solutions

- Optimization of fuel gas consumption

- Improving network operations

- Move to hydrogen

Leak detection solutions

Transporting any fluid should involve as much leak mitigation as possible. While most oil and gas pipelines don’t leak, it’s nearly impossible to completely protect a pipeline against leaks, especially when there are influences outside the pipeline operator’s control such as natural causes, excavation and external and internal corrosion.

Also, when the fluid in a pipeline is hazardous to people and the environment, leaks run the risk of emitting a substantial amount of greenhouse gas emissions.

Detecting these types of leaks early can result in the leak being isolated and repaired with a reduced impact on the climate.

A comprehensive API Recommended Practice 1175 program is the best way to select and manage leak detection because it’s a standard written by a committee of pipeline operators with leak detection experience from the industry. Using this program gives pipeliners the best chance to detect a leak, take the correct actions to minimize the volume of fluid spilled or gas released and cause the least damage to the environment.

Optimization of fuel gas consumption

One of the main greenhouse gas emissions is caused by compressor stations in a gas network, so the optimization of fuel gas consumption makes a big difference in the reduction of gas emissions.

The general aim of a gas optimizer is to allow pipeliners to operate their networks more efficiently. Offline planning tools can be used to cover basic optimization, but these are time consuming because they require a user to set up multiple scenarios each with multiple demand profiles and then analyze the results to establish the most efficient operating plan for each scenario.

An alternative would be an online, accurate, automated gas optimizer but due to the compressible nature of gas, the transient and complex operations of gas networks and the large to massive scale calculation problems, no one has successfully created a numerical solution yet.

Recent technological advances make online gas optimizers a possibility through the computational power of the cloud. The optimizer can then explore a much larger number of possible operating scenarios for a given gas-day plan than an offline planning tool.

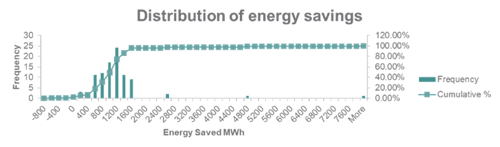

The optimizer will then identify and recommend an operating plan that requires the least energy (emissions/cost). Potential energy savings are visible in figure 1 which uses the example of gas transmission network of 2,600km (1,616 miles) with diameters of 32 inches to 16 inches.

Figure 1: Potential energy savings by the gas optimization system

As the compressors use gas from the pipeline, the energy saved is directly related to a reduction of gas consumed. In figure 1 for example the total energy saved is 112,200 MWh per year which is equivalent to 10,635,000 Nm3 (375,571,000 cubic feet) of natural gas.

Improving network operations

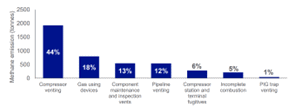

Gas venting is one of the main sources of methane emissions and can be caused by purging for works, regular emissions of devices, starts and stops of compressors and unexpected incidents (see figure 2).2 Improving network operations is vital to reduce gas venting and its greenhouse gas emissions.

Figure 2: National Grid’s estimates of greenhouse gas emissions

To provide operational support like capacity evaluation, pipeline simulation software like Atmos SIM can be used for capacity evaluation to address the complex and time/cost/resource consuming effort needed to establish the accurate capacity of complex gas networks for short and long term gas planning and transport commitments.

To reduce greenhouse gas emissions, pipeliners can use a combination of real-time simulation and look-ahead modeling to prevent gas venting when the pipeline pressure increases. Gas emissions can be prevented further when the same simulation software is used to schedule compressor operations so that they are not stopped and started frequently.

Planning for the move to hydrogen

The move to hydrogen and renewable natural gas will reduce greenhouse gas emissions. To help with the transition, pipeline simulation software like Atmos SIM will be an essential tool in different ways. Hydrogen molecules are much smaller than natural gas molecules so pipeline leaks will occur more easily. For this reason modelling accuracy is crucial when hydrogen is introduced to natural gas pipelines.

To minimize the impact on climate change, simulation software should consider the following key areas for hydrogen blend calculations:

- Equations of state - hydrogen/natural gas blends need to be accurately modelled from 0% to 100% hydrogen

- Pipe equations - determine the friction factor of a pipe or how much pressure drop there will be due to friction for a given flowrate

- Security of supply maintenance - the energy density of methane gas is higher than hydrogen so blending both will need to consider whether the existing pipeline infrastructure can deliver the required energy

The use of simulation software in the move to hydrogen can provide medium/long term planning support, allow the operators to make decisions on pipeline network reinforcement in advance and reduce major operational issues like greenhouse gas emissions.

What you can do now to plan the reduction of your greenhouse gas emissions

The role of hydrogen will continue to play a crucial role in the transition to carbon neutral energy so an effective leak detection system has never been as important.

Leak detection paired with simulation software can help pipeline companies reduce greenhouse gas emissions in the event of leak.

To learn more about reducing a pipeline’s gas emissions download the paper in full as first presented at the International Pipeline Conference and Exposition 2022.