Using pipeline simulation to increase pump and compressor efficiencies

Pipeline pumps and compressors

Although pumps and compressors may operate on broadly similar principles, it’s important to be able to distinguish the two. In pipelines, pumps are used for transporting liquids and compressors are used for transporting gases.1

Simulating them presents a range of special challenges and not every application in a pipeline simulator needs to model them closely. In a real-time model deployed for only leak detection for example, instruments are required to be good enough so that they can isolate each station’s interior.

So, in this application it’s important that the simulation doesn’t model pumps or compressors or depend on them being accurate.

However, in other applications, the modeling of pumps and compressors plays a vital role in ensuring the pipeline simulation is accurate and being able to troubleshoot in real-time scenarios.

When offline, they are important to design studies for engineers to consider potential changes in pipeline operations or future upgrades. It’s particularly interesting to see how pumps and compressors perform in different scenarios. They can for instance look at long-term savings that can be made by optimizing operations, saving power or by deciding what to do during scheduled maintenance.

In this article we’ll explore:

- Pump or compressor performance

- Types of pumps and compressors

- Pumps in liquid pipelines

- Compressors in gas pipelines

Pump or compressor performance

If pump performance data is not available, a quick way to model a pump is to use an ideal pump. An ideal pump or compressor immediately delivers a set amount of useful energy without restriction, doing exactly as it’s told by the user.

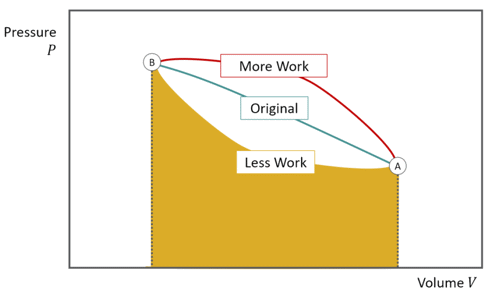

Figure 1: A pressure-volume diagram of a compressor

Any pump or compressor affects fluid from the outside world in two ways:

- Transferring heat

- And doing work on it

Both are impossible to calculate directly because they are path-dependent quantities. The way to overcome this is to calculate heat and work indirectly. A thermodynamic property is a state function, which means that it is purely a function of the thermodynamic variables describing the current state of the system (such as pressure and temperature)1 This type of variable is useful to work with as it changes by the same amount regardless of the path taken.

There are four core factors to consider when evaluating a pump or compressor’s performance. They are:

- Power, work and head - helps to select an appropriate driver or predict what power an existing driver will draw in a given scenario

- Temperature rise - accounts for changes in the density of the product that may lead to inefficiencies in the pipeline

- Enthalpy and entropy - measures of energy and energy degradation

- Efficiency - performance calculations

Types of pump and compressor

Almost all pumps and compressors work by one of two fundamental principles:

- Centrifugal - work on the dynamic principle, they don’t push directly

- Reciprocating - work on the principle of positive displacement (PD)

Most widely deployed pumps and compressors on large pipelines today are centrifugal.1 The increase in the cross-sectional area of this principle reduces the velocity raising the pressure the product is discharged from the pipeline. In addition, larger flow rates are possible, relating to the efficiency of the pipeline.

Pipelines are designed with a high degree of resilience. This helps to ensure that it can deliver at least some of the specified flow rate even if a given pump or compressor is unavailable.

Pumps in liquid pipelines

The density of an almost incompressible liquid only varies slightly. When pumping very compressible liquids such as liquified petroleum gas (LPG), special equations of state are used to calculate the change in density with pressure and temperature. Even in a perfectly efficient pump, a compressible liquid has an isentropic (relating to equal or constant entropy) temperature rise.

Because pumps handling compressible liquids are not isentropic, they are approached in a similar manner in Atmos Simulation (SIM) Suite. For this, we calculate the power and discharge temperature via integration in the same manner as for a gas compressor.

One way Atmos SIM can be used to assist pumping operations is with surge relief strategies via control logic. This protects the pump and helps to maintain safe conditions. Atmos SIM does not let a pump operate in a surge condition. If a pump map doesn’t have the positive slope region, it automatically hides that and assumes an almost-flat negative slope. The Atmos SIM optimizer always avoids operating any pump in its surge region.

Figure 2: Atmos SIM shows how some pumps can run down to zero flow without surging

Compressors in gas pipelines

Compressible fluid changes in temperature as it is pressurized because its density changes. This means it requires more work to compress a mass of gas than to pump the same mass of incompressible liquid.

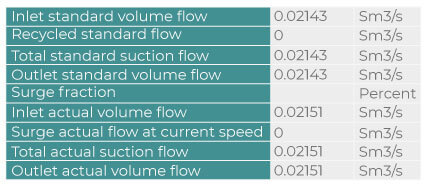

Atmos SIM assists pipeline operations in many ways by modelling compressors, for example, fuel gas consumption calculation, maintenance planning and demand management. It can also help by modeling a badly operated compressor going into surge and how it can recover from it. Recycling some of the flow rate from the discharge side back to the suction side is one of the anti-surge measures that can be implemented. The centrifugal compressor model in Atmos SIM includes a convenient internal recycle to automate this activity. With this build-in surge control, the operating point moves to the right, which increases volumetric flow at the same head until it’s past the surge line.

References

1 “The Atmos book of pipeline simulation”

Download chapter seven Order the book

Ready for chapter eight?

Every action has a consequence when it comes to pipeline operations. Chapter eight details how pipeline simulation can assist with not only day-to-day tasks, but also to answer key questions for the future.