Written from the field by Senior Project Engineer Oliver Port

The challenge of single ended monitoring

On rising sewer mains, there’s a common but difficult problem: what happens when you only have access to one end of the pipeline?

Traditionally, high performance leak detection systems rely on sensors installed at both the inlet and outlet. That’s a non-starter for many wastewater pipelines, where the only accessible location is the inlet at the pumping station. This limitation was the starting point for one of our recent projects on a challenging rising sewer main in the UK.

To monitor these assets cost-effectively, we needed a solution that worked from just one end, without compromising sensitivity or reliability.

Innovation born in the field

We trialled a single ended leak detection solution on site in early 2024, installing an intrusive pressure sensor and an Atmos Eclipse unit equipped with an ultrasonic flow meter and geophone to begin gathering pipeline data.

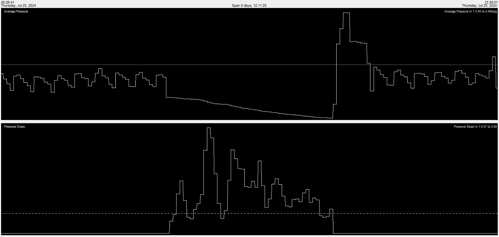

This field data played a key role in developing the Atmos Sentinel system, designed specifically for single ended installations. Instead of relying on instrumentation at both ends, Atmos Sentinel monitors pressure and vibration at the inlet to detect signs of leakage. During shut-in, the system was able to estimate the location of a leak along the pipeline (see Figure 1).

Figure 1: Shut-in pressure trend used for leak detection and location. The pressure change enabled the estimate of a leak elevation approximately 3 m above the pumping station.

During both controlled test scenarios and live operations, Atmos Sentinel demonstrated it could detect leaks as small as 7% of reference flow during running conditions and 1% of reference flow during shut-in periods.

Real leaks, real detections

During the project, the system identified multiple genuine leak events. In one case, the detected leak caused a valve chamber just outside the pumping station to overflow with sewage (see Figure 2).

Figure 2: Valve pit overflow near the pumping station. The overflow was caused by a leak identified by Atmos Sentinel during live monitoring.

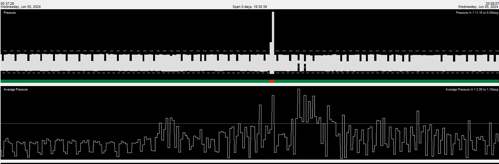

Several high-pressure transients and short-lived pressure spikes were also detected in the run-up to these events (see Figure 3). Providing these insights will enable water utility companies to get ahead of issues before they escalate.

Figure 3: Brief 11 barg pressure spike detected at pipeline startup. Atmos Sentinel flagged this transient, which preceded a confirmed leak event.

Atmos Sentinel: built for simplicity and flexibility

The Atmos Sentinel models have been developed specifically for pipelines where access is limited, such as rising mains with only a single tapping point. It comes in two configurations to suit different monitoring needs:

Real-time installation

Provides live leak detection and transient monitoring. Atmos Sentinel samples pressure, vibration and (where available) flow data at high resolution, and processes it onboard to reduce transmission bandwidth. It then transmits alerts via 4G or radio when events are detected.

Offline logging

Records high-frequency pressure and vibration data locally for up to 96 days. This version is ideal for long-term studies or where live comms aren't available or needed. Data is manually downloaded for retrospective analysis.

Both options are:

- Battery powered, with an option for solar or mains input if needed

- Designed for above or below ground installations

- Equipped with edge analytics for onboard processing

This flexibility makes Atmos Sentinel well-suited to both proactive monitoring and in-depth investigations, without overcomplicating deployment.

Bringing innovation back to the field

As someone who’s hands-on with these assets, it’s rewarding to see a solution that blends innovation with practical field application. Rising sewer mains will always be difficult to monitor, but with the right tools, we can manage them confidently, even when we’re working with just one access point.

Next up: How a pressure spike predicted a major sewer leak

In the next blog, I’ll walk through how a split-second pressure spike gave us the first warning of a real leak, days before it overflowed onto the site.