CO2 pipelines are different, and leak detection must evolve

As carbon capture and storage (CCS) projects move from planning into delivery, CO2 pipelines are becoming a critical enabler of the energy transition. Without safe and reliable transport, captured carbon dioxide cannot reach storage or utilization sites, placing significant pressure on pipeline operators to demonstrate high standards of safety, availability and environmental assurance.

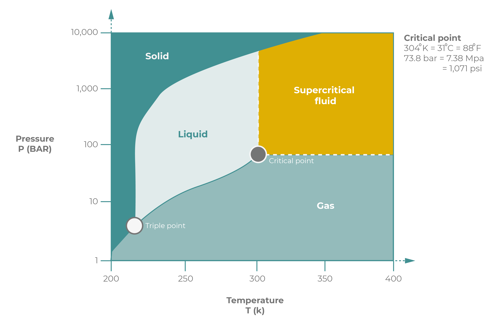

Unlike traditional oil and gas pipelines, CO2 pipelines often operate in dense or supercritical phase (see Figure 1) and can be sensitive to pressure, temperature and impurity changes. These characteristics introduce new operational and integrity challenges, making effective leak detection a foundational requirement rather than a secondary safeguard. As a result, the future of CO2 pipeline operations is being shaped by advanced leak detection and simulation technologies designed specifically for this service.

Figure 1: The phase diagram illustrates how CO2’s state changes with variations in temperature and pressure

In this blog by Vice President (Sales) Peter Han, he covers:

- Statistical leak detection built for CO2 service

- Pipeline simulation as a strategic enabler, not just a design tool

- Preparing for evolving regulation and long-term operation

- Why this matters now

Statistical leak detection built for CO2 service

One of the most important technologies shaping CO2 pipeline leak detection is statistical leak detection based on corrected flow balance.

Atmos Pipe uses advanced statistical leak detection techniques to compare expected pipeline behavior with live pressure and flow data. This approach is particularly well suited to CO2 pipelines, where operating conditions frequently change and steady-state assumptions can lead to missed leaks or false alarms.

For dense phase CO2 pipelines, a leak can trigger rapid pressure and temperature changes that are difficult to interpret. Atmos Pipe is designed to distinguish these operational transients from genuine leak signatures. It remains reliable during other normal operational events such as start-ups, shutdowns and flow variations. This gives operators earlier detection, higher confidence and a clearer understanding of what is happening in the pipeline when it matters most.

From a business perspective, this translates into faster response times, reduced operational disruption and stronger evidence of due diligence for regulators and project partners. Atmos Pipe is currently deployed on CO2 pipelines across the world, the most recent case being an operations project in Oceania.

Pipeline simulation as a strategic enabler, not just a design tool

Pipeline simulation plays a central role in shaping the future of CO2 pipeline operations.

Atmos Simulation (SIM) Suite allows operators to model how CO2 behaves under real operating conditions, including the effects of phase change, impurities, elevation profiles and transient events. These simulations support leak detection by improving alarm thresholds and help operators understand how CO2 pipelines will respond to abnormal events.

Beyond leak detection, simulation supports commercial and strategic decisions. For CCS projects, it helps operators plan capacity, assess operational flexibility and demonstrate pipeline performance to investors and regulators. When simulation and leak detection are integrated, operators gain a more complete picture of both risk and opportunity across the pipeline lifecycle.

Preparing for evolving regulation and long-term operation

Regulatory expectations for CO2 pipelines continue to evolve, particularly as CCS projects scale and public visibility increases. While specific rules vary by region, the direction is clear. Operators are expected to demonstrate proactive monitoring, rapid leak detection and credible risk management strategies.

In the United States, PHMSA has proposed updates to federal pipeline safety rules that would strengthen leak detection and monitoring requirements for carbon dioxide pipelines under Part 195. Although still in proposal form, this signals growing regulatory focus on CO2 pipeline leak detection. Leak detection technologies that are flexible, auditable and scalable allow operators to adapt as regulatory frameworks mature. By deploying advanced systems early and seeking the support of a regulation compliance service, operators reduce the risk of costly retrofits and position themselves to respond confidently to future compliance requirements.

Why this matters now

CO2 pipelines are no longer niche assets. They are becoming essential infrastructure underpinning global decarbonization strategies. Decisions made today about leak detection and simulation technology will shape safety performance, regulatory confidence and commercial resilience for decades.

How Atmos International supports the next generation of CO2 pipelines

Atmos brings decades of experience in pipeline simulation and leak detection to the challenges of carbon dioxide transport. Through technologies such as Atmos Pipe and Atmos SIM Suite and our leak detection regulation compliance service, we are already supporting operators as they adapt proven approaches to the specific demands of CO2 service.

As CCS infrastructure expands, pipeline leak detection and simulation are not simply a technical requirement. It is a strategic investment in safety, credibility and long-term success.

Join us at the CO2 Pipeline Summit to discuss how advanced leak detection and simulation can support safe, scalable CO2 transport