Strengthening safety requirements for carbon dioxide pipelines

The US Department of Transportation (DOT) proposed a new rule to strengthen safety requirements for carbon dioxide (CO2) and hazardous liquid pipelines. While the notice of proposed rulemaking (NPRM) for leak detection in CO2 pipelines has since been withdrawn, the proposals it contained continue to offer a blueprint for the future of leak detection regulation.

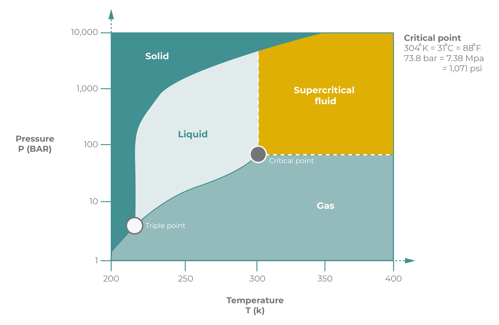

Figure 1: The phase diagram illustrates how its state changes with variations in temperature and pressure

A significant element of this NPRM would have made leak detection systems a requirement for CO2 pipelines, including CO2 transported as a supercritical phase fluid (see Figure 1). If this NPRM is reintroduced, operators should exercise caution and be prepared to implement the requirements.

In this blog, Vice President Peter Han discusses what the NPRM meant for CO2 pipelines, a summary of the NPRM and what’s next for leak detection in CO2 pipelines after the NPRM withdrawal.

What did this NPRM mean for carbon dioxide pipelines?

Under this NPRM, CO2 pipelines would have been required to have a leak detection system that operates in accordance with part (§) 195.134 of title 49 from the Code of Federal Regulations (CFR).1

§ 195.134 explained

Commonly relevant to hazardous liquid pipelines without gas in the liquid (single phase), this ruling would have also required CO2 pipelines to have a system for detecting leaks.

Under this ruling, an operator would have been required to:

- Evaluate the leak detection system’s ability to protect the public, property and environment.

- Perform necessary modifications to ensure the leak detection can continue to protect the public, property and environment.

- Consider the following factors during their evaluation: length and size of the pipeline, type of product being transported, the speed of leak detection, location of nearest response personnel and leak history.

Any computational pipeline monitoring (CPM) leak detection system installed on a CO2 pipeline would also have to comply with American Petroleum Institute (API) recommended practice (RP) 1130.

Pipelines operating in accordance with § 195.134 would also have needed a leak detection system in place that complies with § 195.444.2

§ 195.444

Under § 195.444, PHMSA states that an effective system for detecting leaks must be in place on pipelines that complies with §§ 195.134 or 195.452, depending on which ruling is more appropriate to the pipeline.

§ 195.452

§ 195.452 refers to pipeline integrity management in high consequence areas (HCAs) and is relevant to hazardous liquid and carbon dioxide pipelines that could affect an HCA.

More information on HCAs and § 195.452 can be found in this blog.

The NPRM summarized for pipelines transporting liquid phase or supercritical carbon dioxide

For liquid phase or supercritical CO2 pipelines, this NPRM proposed that not only must there be a leak detection system in place, but that it must be a CPM system too.

To fulfil requirements set in §§ 195.134(c) and 195.444(c), the CPM leak detection system would have needed to meet the requirements of API RP 1130.

Lessons from the withdrawn NPRM

Although the proposed rule for CO2 pipeline leak detection has been withdrawn, it revealed clear regulatory intentions.

The NPRM highlighted leak detection as a top priority, proposing mandatory systems, including CPM, for CO2 pipelines and alignment with API RP 1130.

While not currently enforceable, these proposals offer a strong indication of future direction. Operators who proactively assess and strengthen their leak detection systems now will be better positioned if similar rules are reintroduced and will demonstrate a strong commitment to safety and environmental protection.

Atmos supports this forward-thinking approach with services that align with regulatory best practices, even in the absence of finalized rules.

Prepare your pipeline operations for future regulations

Even though the NPRM is currently withdrawn, Atmos supports proactive compliance and safety strategies. Our Regulation Compliance Service can help you align with anticipated standards.

Leak detection regulation compliance service Guidance on leak detection regulations