Removing guesswork and uncertainty for pipeline controllers

Pipeline operations are constantly evolving, which is why they must be evaluated continuously. Whether it’s a change in the pressure of the gas network or the transition to hydrogen energy, all these evolutions pose challenges for pipeline controllers to ensure safety and efficiency of their operations.

- How will the existing gas pipeline infrastructure cope with changes?

- How to keep track of product quality to ensure customer delivery is on-spec?

- Will the pipeline allow for increased demand?

Pipeline simulation can be used as a powerful decision support tool to answer all these questions and more, helping to remove the guesswork and areas of uncertainty for pipeline operators alike.

Simulation can be used offline for planning, capacity analysis and detailed transient studies or online using real-time data from a distributed control system (DCS) or supervisory control and data acquisition (SCADA) system.

In this article we’ll address the core challenges pipeline simulation helps overcome including:

- Understanding existing pipeline infrastructure

- Calculating ‘what-if’ scenarios

- Training the next generation of pipeline operators

- Improving pipeline safety

- Optimizing pipeline efficiency and ensuring the quality of the product to customers

Understanding existing gas pipeline infrastructure

As needs and demands change, it’s important to understand what the existing pipeline infrastructure can cope with. The transition to hydrogen blends, or pure hydrogen for energy, for example presents the challenge of understanding when and where network reinforcement may be required.

The European Hydrogen Backbone report1 outlines that as part of Europe’s move to hydrogen energy, almost 23,000 km of H2 pipelines by 2040 will consist of 75% repurposed natural gas infrastructure. This means it’s vital for the operators to understand how the shift to hydrogen and hydrogen blends will impact the pipelines.

Pipeline simulation, such as Atmos Simulation (SIM) Suite makes it possible to model all aspects of your pipeline infrastructure on a canvas. When used offline, pipeline operators can gain an accurate understanding of what the pipeline infrastructure can cope with.

As shown in figure 1, pipeline operators need to know if this theoretical network will cope with future demand and how hydrogen will impact network capacity.

Figure 1: Theoretical transmission network

The pipeline capacity of this network is constrained by:

- Supply locations

- Network topology

- Demand pressure requirements - main constraint is ‘Violetwick’ at the extreme of the network to an industrial consumer with a minimum delivery pressure requirement of 3500 kPa

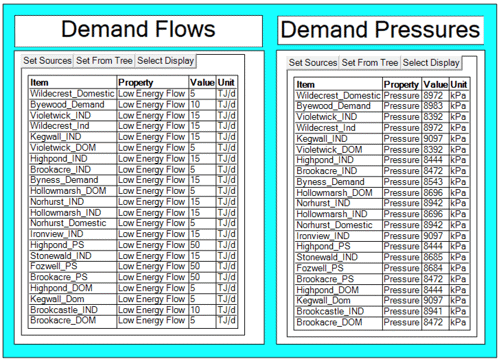

We need to know if this network can cope with predicted future demand and how the concentration of H2 will affect network capacity. A base case for 100% natural gas is constructed using the current Maximum Daily Quantity (MDQ) at all demands, shown in figure 2. The results show a total demand of 345 Tj/d.

Figure 2: A base case using MDQ

This case gives a starting point for the analysis. The analysis repeats a 24-hour cycle, enough for the network to reach steady-state at new conditions. Total demand is increased every 24 hours, divided up as per the starting state.

Software like Atmos SIM makes this task easier with demand groups. In figure 3 all demands were added to a single group, input to the scenario is one single overall demand figure. Once the minimum pressure constraint is violated, the demand is reduced to maintain pressure. The point when this happens is deemed as the maximum capacity.

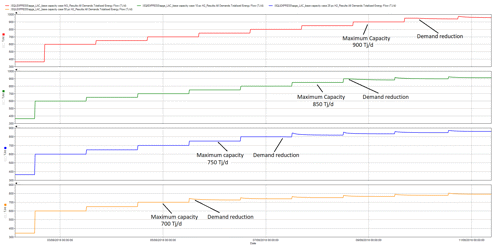

The impact of hydrogen blend varies from one network to another. As shown in figure 3 it’s clear that the maximum capacity is reduced as hydrogen concentration increases in the theoretical network. The maximum capacities calculated are:

- 100 Natural gas 900 Tj/Day

- 10% Hydrogen 850 Tj/Day

- 25% Hydrogen 750 Tj/Day

- 50% Hydrogen 700 Tj/Day

Figure 3: Hydrogen blend maximum capacity calculated by Atmos SIM (Red 0%, green 10%, blue 25% and orange 50%)

A simulation like this can easily be used to help determine if future demand can be met as the pipeline infrastructure stands now or whether changes in infrastructure are needed

Calculating ‘what if’ scenarios

Pipeline simulation provides control room staff with decision support by quickly and safely testing future scenarios. Using tools such as Atmos SIM Online provides predictive modeling, (also known as what-if modeling) and look-ahead modeling so future scenarios can be tested.

You can look at what impact a pipeline leak or sudden failure of stations or equipment would have if it were to happen right now, helping to anticipate the risks that develop in real-time, assess their consequences and take actions. What-if scenarios also help answer questions around how the pipeline would manage under unplanned events like compressor outages and how it would affect the security of supply.

In a dynamic market, constant changes in gas price could mean some variations in the supply and demand would increase the financial margin of a network significantly. The feasibility assessment of the network can be done within minutes accurately if Atmos SIM is running online.

Being able to plan for situations like this means pipeline operators can:

- Gain an understanding of how to cope with a variety of situations

- Have confidence in operational decisions

- Carry out survival-time analysis

- Have contingency plan

- Gain material for training a variety of scenarios to new and existing operators

- eg hospitals, power plants

All scenarios can be saved in the scenario manager within Atmos SIM and ran again as needed with no additional set-up. Alarms are generated if the planned future operating conditions will violate safe operating limits.

Training the next generation of pipeline operators

Training is always a challenge when it comes to pipelines. How do you effectively prepare a pipeline operator to recognize abnormal conditions like leaks without experiencing them in real life?

Simulation can help here too, with tools like Atmos Trainer presenting a user-friendly way to train new operators. Mimicking the behavior of the pipeline and assessing the operator’s response to the arising situations mean that pipeline simulation helps to rehearse not only routine tasks but also abnormal operating conditions.

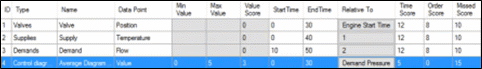

An operator’s competency on how to handle a situation is assessed on how they execute each appropriate measure within the proper timeframe, simulating behavior beyond just that of the pipeline physics such as emergency shut-down (ESD) sequences and pump start-up logic. Figure 3 shows the scoring in Atmos Trainer, demonstrating how the scoring module assesses the user-input value against the timing of the action against the procedure. It helps training new members of the team and keeping existing operators in practice.

Figure 4: Atmos Trainer scoring module

You can even take historic events to learn from near-misses. Having a training mechanism in place like this also satisfies the regulators, building confidence that good standard operating procedures (SOP) and guidelines are in place.

Improving pipeline safety

Safety is one of the biggest concerns for pipeline operators. The safety of the pipeline is not only crucial for meeting the differing sets of regulations across countries but protecting the environment and communities from the devastating consequences that pipeline incidents can have. Optimizing safety is not just relative to the structural integrity of the pipeline, but also the people operating it. There’s a very human side to safety, where incorrect operation can directly contribute to disasters.

Although small stints exceeding the maximum allowable operating pressures (MAOP) might be permissible, the stringent safe operating limits (SOL) must never be exceeded. Pipeline simulation enables you to set alarms that trigger if the SOL is exceeded for planned future scenarios, meaning that pipeline operators can make the right decisions before disaster strikes, a more preventative approach to pipeline safety.

Accidents often occur from a series of failures. Whether they are to do with the infrastructure of the pipeline, how it is operated or the management process that are put in place. Pipeline simulation helps to avert from a crisis that hasn’t happened yet with what-if scenarios and trains pipeline operators to learn from the previous mistakes of historical events.

Optimizing pipeline efficiency and ensuring the quality of the product to customers

Aside from safety, there’s also pressure on pipeline operators to deliver on tight deadlines, ensuring the product arrives with the customer on-time and on-spec. As we know, pipeline networks can often be complex and diverse, transporting a variety of different products to various locations.

As previously discussed with the transition to hydrogen example, pipeline simulation helps ascertain maximum capacity. This helps to understand how much pressure the pipeline can be put under to maintain safe conditions while optimizing the pipeline to run as efficiently as possible.

Gas composition or quality tracking is an essential feature that runs online, making it easy to not only locate and give an accurate estimated arrival time of the gas, but also assess the quality to ensure it’s delivered on-spec.

A decision-support tool for pipeline operators

Ultimately, pipeline simulation is here to empower pipeline operators to make smarter decisions for their pipelines, helping to overcome core challenges, like uncertainties around infrastructure and how it will cope with changes like the move to hydrogen energy. Providing quick and easily accessible answers with relation to contingency planning based on the limits of the pipeline infrastructure, it ensures that the customers’ demands are met even if some unexpected events occur.

It’s also becoming a useful tool for training new and existing pipeline operators. With an easy-to-use scoring system to assess the appropriate steps of action for both normal and abnormal operating scenarios such as demand changes and loss of supplies.

References

1 https://gasforclimate2050.eu/sdm_downloads/european-hydrogen-backbone/