Key pipeline solution updates

Despite the ongoing uncertainties around the world, we’ve continued with ongoing support for our customers in the fourth quarter of 2025.

Quarterly achievements

- 8 thefts detected

- 7 SATs completed

- 7 FATs completed

- 3 training sessions delivered

- 3 customers upgraded to the latest software

Below is a selection of success stories from this quarter at Atmos, including:

- Theft detection highlights

- Real-time pipeline simulation supporting operational insight

- Aviation fuel network monitoring and testing

- Supporting our customers in all weathers and all conditions

Read our quarterly update below to find out more.

Theft detection highlights

Fuel theft on a long distance crude oil pipeline in India

Atmos Wave detected a theft on a long distance crude oil pipeline in India that has been monitored by the system for several years. The asset consists of twin 18 inch pipelines spanning more than 470 km.

The theft occurred on a looped section of the pipeline. Atmos Wave estimated the theft location within 600m of the confirmed field location (see Figure 1), demonstrating strong location accuracy on a complex, long distance pipeline.

Figure 1: The theft identified by Atmos Wave

Multiple illegal tapping events detected on an Indonesian crude oil pipeline

In a one month period last quarter, Atmos Wave detected multiple illegal tapping points on a crude oil pipeline in Southeast Asia. The pipeline is approximately 265 km long, 8 inches in diameter and routed through a combination of remote and urban environments.

Despite challenging operating conditions, including variable wave speed, slack flow and intermittent communications, the system performed reliably during a sustained and targeted theft campaign (see Figure 2).

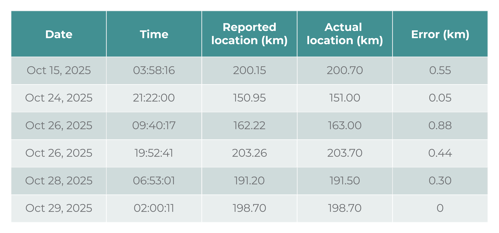

Figure 2: Examples of theft events located in October 2025. The pipeline remains under close surveillance, with heightened vigilance due to repeated theft activity.

Early theft detection during system deployment in Latin America

Atmos was recently commissioned to support theft detection on a pipeline in Latin America. During the first day of monitoring, which focused on data collection and system tuning, several potential illegal tapping points were identified.

One valve was successfully located within the same day, with a location precision of approximately 6 meters. Ongoing tuning is being carried out in collaboration with field teams to further optimize detection performance.

This early result demonstrates the value of deploying theft detection capability as early as possible, even during commissioning phases.

Figure 3: Theft site location (left), the barrels used to store the stolen fuel (top right), and the hose used to transport the fuel between the tap and the barrels (bottom middle and right)

Across all the above incidents, Atmos Wave consistently demonstrated its effectiveness in detecting and locating theft on complex pipeline systems. Using negative pressure wave technology, the system identified illegal tapping activity under a wide range of operating conditions and delivered reliable location accuracy on long distance assets. Its proven sensitivity, low false alarm rates and ability to retain data during communication interruptions allowed operators to respond quickly and with confidence, reinforcing Atmos Wave’s role as a trusted theft detection solution worldwide.

Discover the possibilities of accurate leak and theft detection

Free Atmos Wave product brochure

Real-time pipeline simulation supporting operational insight

Atmos deployed an online hydraulic simulation model from Atmos Simulation (SIM) Suite on a large diameter gas transmission pipeline in North America. The real-time transient model has been running continuously throughout 2025 with minimal interruptions, supporting day to day operational insight.

Configured using live field instrumentation data, the model calculates current linepack, estimates hydraulic conditions at un-instrumented locations, tracks fluid composition changes and supports predictive look-ahead scenarios. It is also used to monitor compressor operating conditions and estimate fuel consumption across the system.

This deployment has demonstrated the accuracy and reliability of Atmos SIM in a real world setting, providing operators with enhanced visibility and confidence in operational decision making.

For increased visibility of your pipeline’s present and future with Atmos SIM (Online)

Aviation fuel network monitoring and testing

Automating hydrant system tightness testing at a major international airport

Figure 4: Atmos engineers testing the tightness monitoring system with an induced leak

Atmos recently supported the configuration, installation and commissioning of a tightness monitoring system (see Figure 4) across a multi-segment airport hydrant fuel network at a major international airport.

A key focus of the site visit was the full automation of the tightness testing process within the airport’s SCADA system. Custom HMI controls were implemented to automate the complete test sequence, including valve isolation, controlled depressurization and re-isolation after test completion. As a result, operators can now independently initiate tests at any time, with the ability to run multiple segment tests simultaneously.

Using the automated workflow, more than 30 tightness tests were successfully completed. The automation significantly reduced manual intervention, saving several days of effort and greatly improving overall testing efficiency. Airport fuel operators were also trained on induced leak testing using Atmos Leak Trial Manifold, along with manual verification techniques to ensure accurate validation of very small leak rates.

Supporting scheduled aviation leak testing through rapid recalibration

Atmos also completed a pressure transmitter recalibration at a Middle East airport (see Figure 5) to support the timely execution of scheduled aviation leak testing activities.

Figure 5: Atmos engineers recalibrating the pressure transmitter

The recalibration was carried out smoothly and enabled testing to proceed without delay, demonstrating the importance of responsive site support, specialist tooling and coordinated logistics in maintaining airport hydrant system compliance.

Discover aviation support from Atmos

Supporting our customers in all weathers and all conditions

Throughout 2025, our team of dedicated professionals have continued to support pipeline operators around the world, regardless of location, environment or operating conditions. From remote and challenging terrain to busy operational hubs, our engineers and specialists have worked onshore and offshore, in extreme heat, cold and everything in between, ensuring systems remain reliable and customers remain supported.

Over the past year, Atmos has continued to provide monitoring, commissioning, maintenance and operational support to more than 250 customers globally across the oil, gas, chemical, water, aviation and mining industries. This consistent delivery reflects not only the maturity of our technologies, but also the dedication and expertise of the people behind them.

As we look ahead to 2026, we remain focused on helping operators detect leaks and theft reliably, respond quickly to incidents and protect critical infrastructure worldwide. Here’s to another year of safe, resilient and effective pipeline monitoring.

Supporting customers worldwide, whatever the conditions